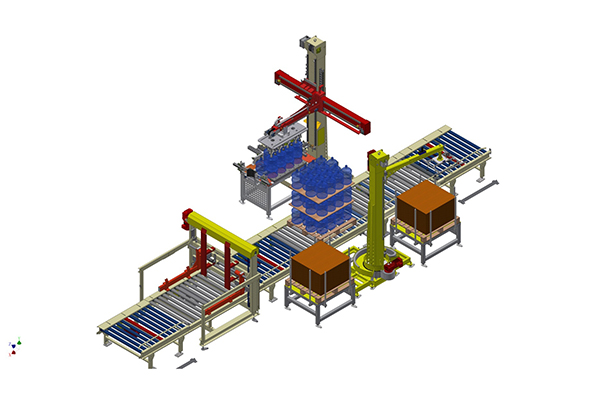

Robot Palletizer For Cartons/Bags/Buckets/Packs

Types of Palletizing & De-Palletizing

Bag Palletizing

Case Palletizing

Carton Palletizing

Box Palletizing

Frozen Food Palletizing

De-Palletizing Systems

Pouch Palletizing

Pail Palletizing

Keg Palletizing

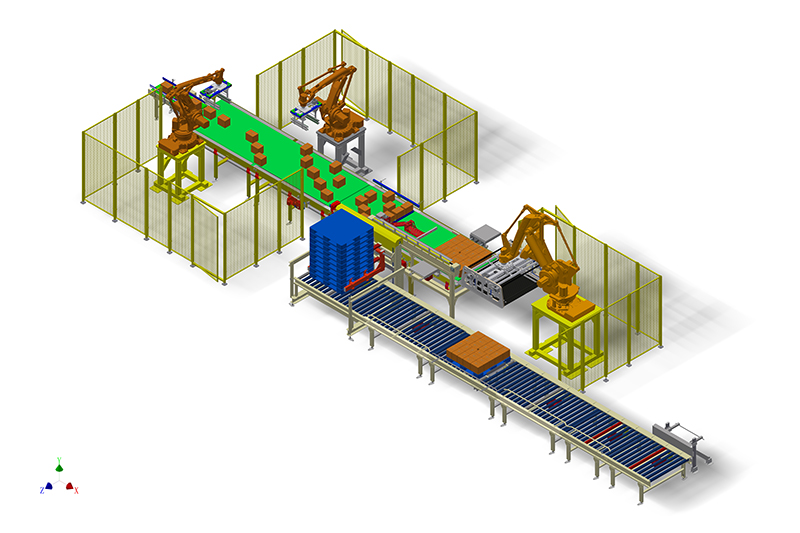

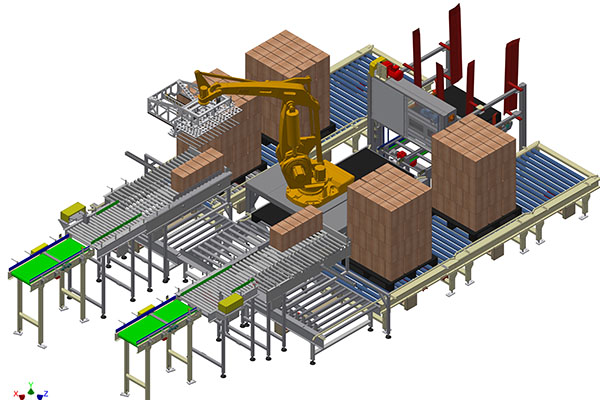

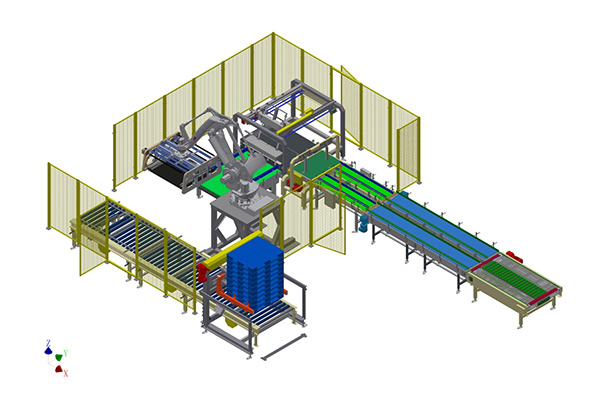

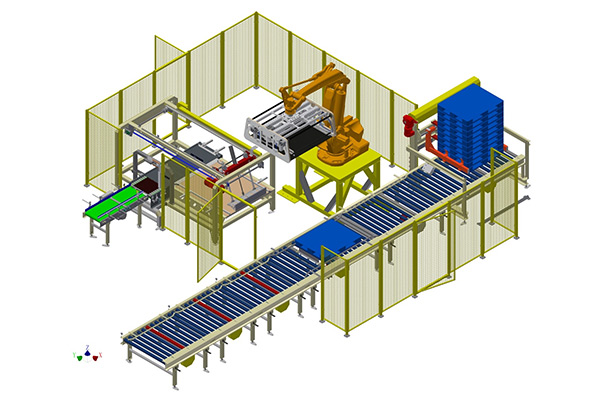

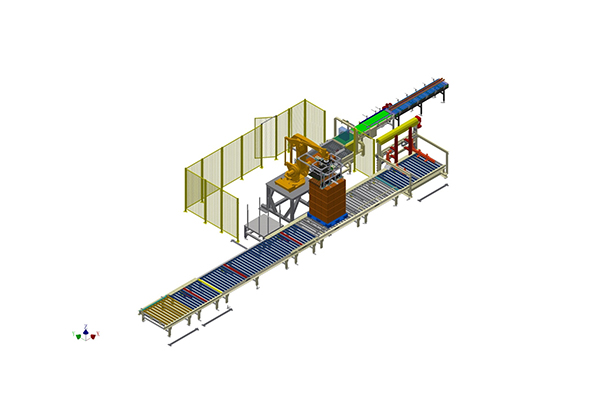

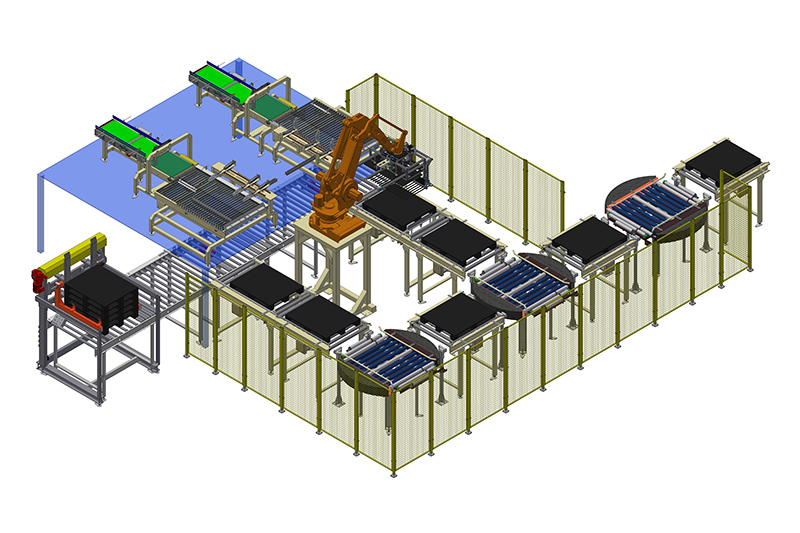

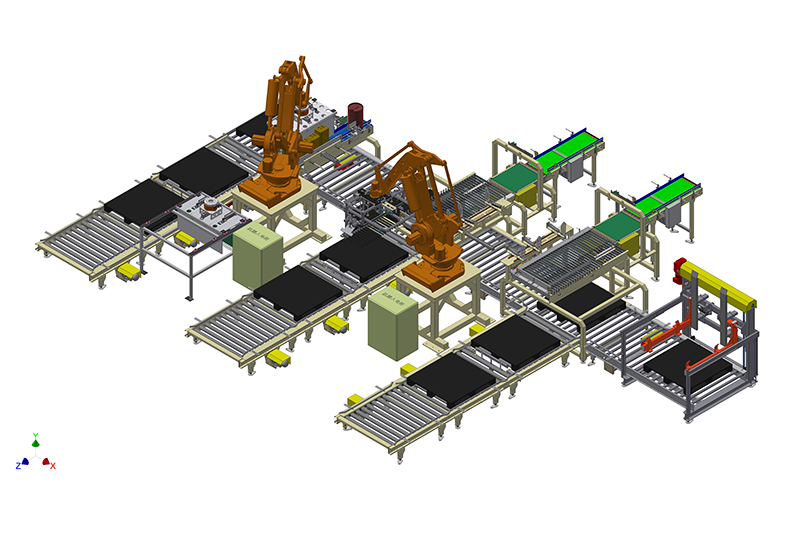

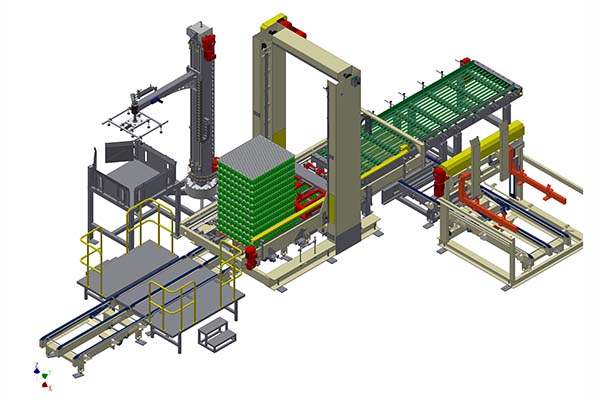

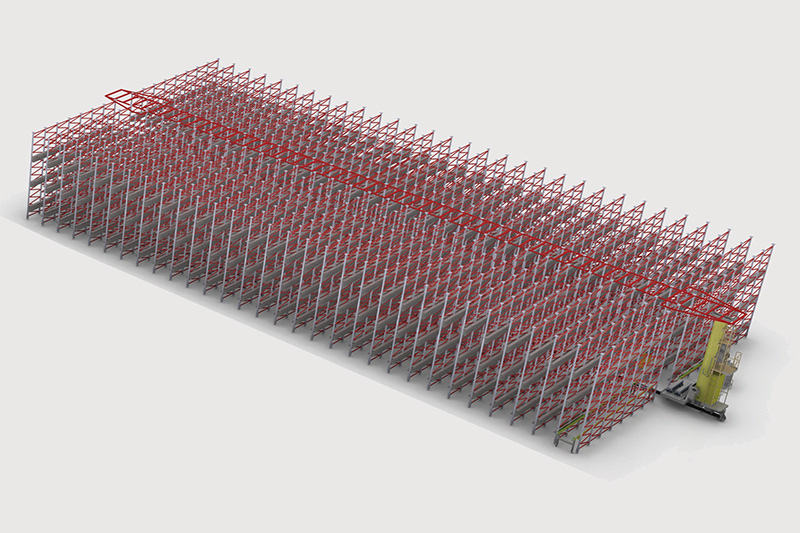

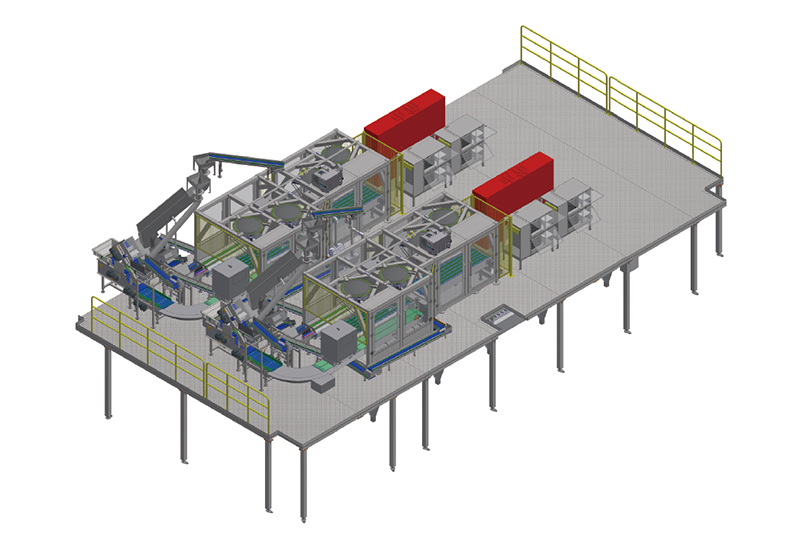

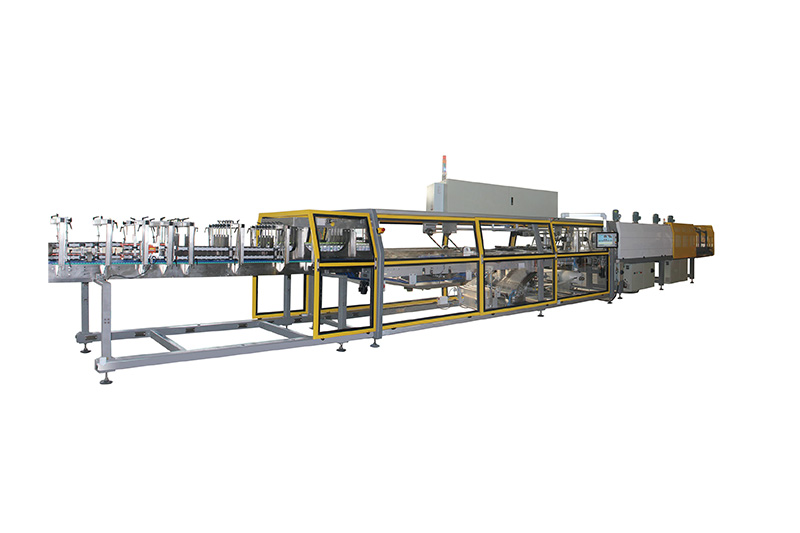

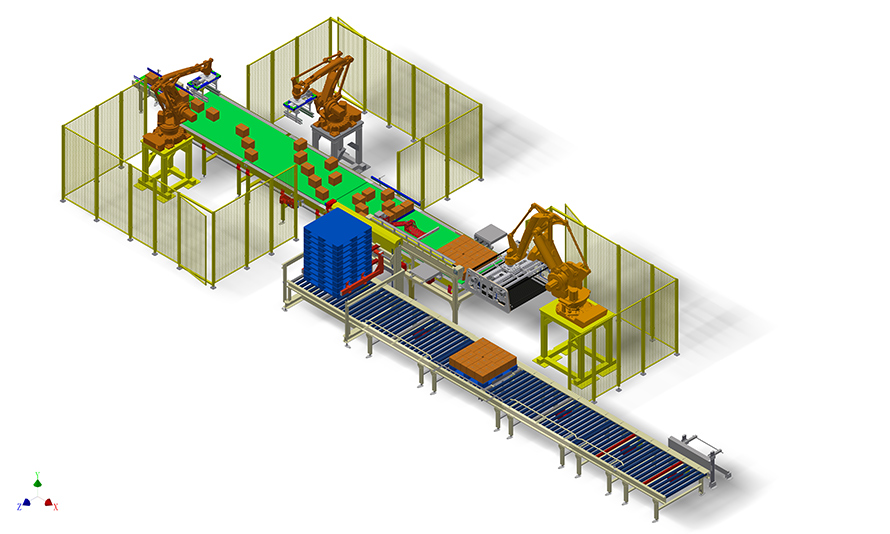

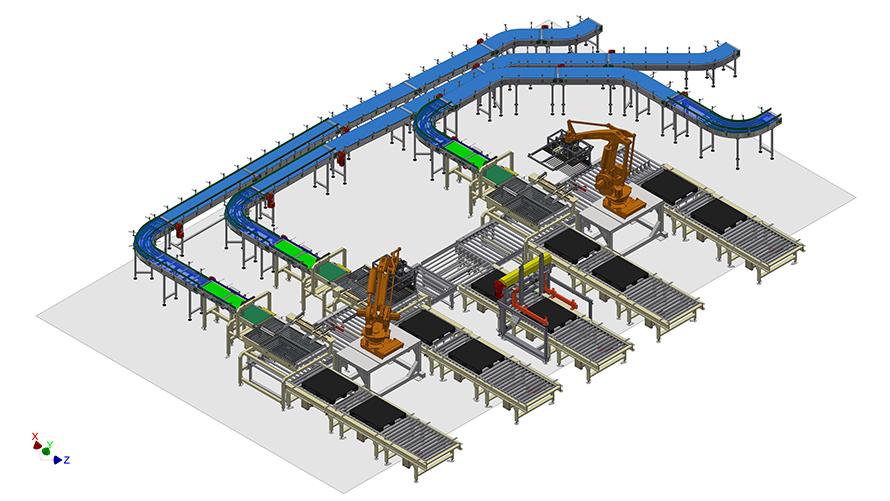

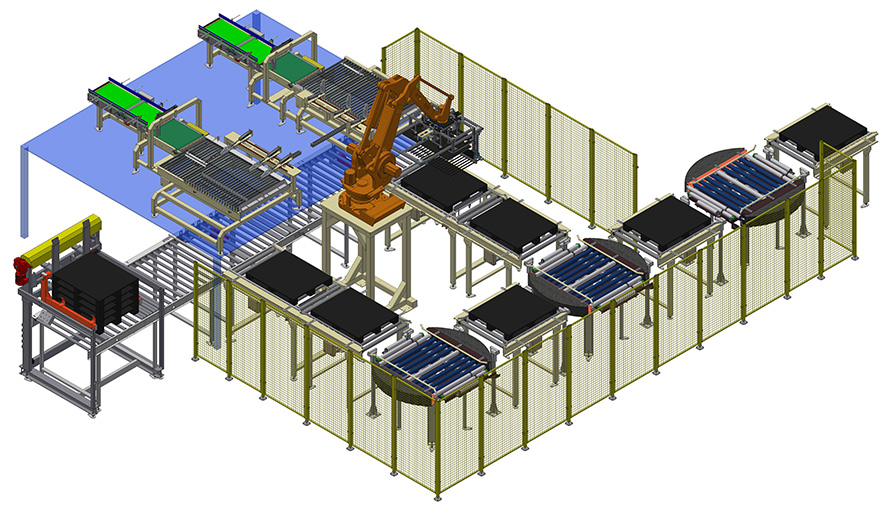

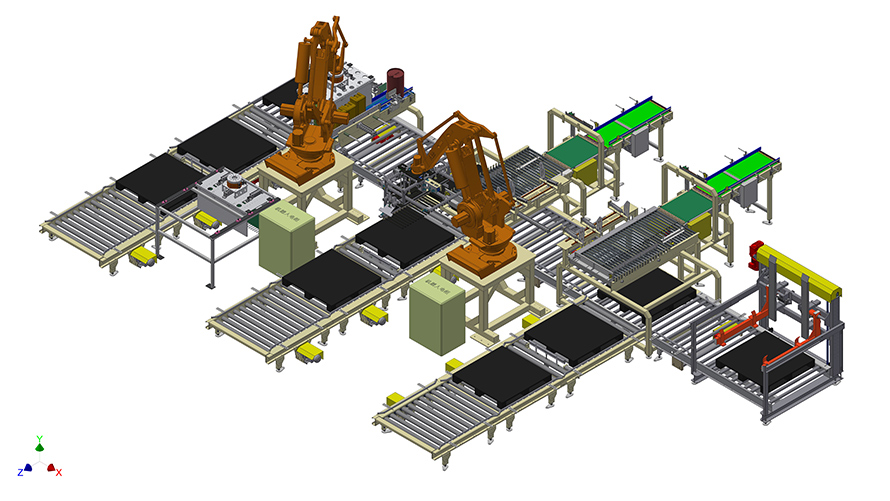

Robot Palletizing Systems

We design standard and customized palletizing systems that can increase productivity and save you money. Modular design offers flexibility, high output, and simple operation. Our robot palletizing systems are flexible and can handle virtually any product, including heavy cases, bags, newspapers, cartons, bundles, pallets, pails, totes or trayed products.

|

SPECIFICATIONS FOR AUTOMATIC ROBOT PALLETIZER |

|||

| Robot arm | Japanese brand robot | Fanuc | Kawasaki |

| German brand robot | KUKA | ||

| Switzerland brand robot | ABB | ||

|

Main performance parameters |

Speed capacity | 4-8s per cycle | Adjust according to products and arrangement per layer |

| Weight | About 4000-8000kg | Depend on different design | |

| Applicable product | Cartons, cases, bags, pouch bags, crates | Containers, bottles, cans, buckets, bags etc | |

| Power and air requirements | Compressed air | 7bar | |

| Electric power | 17-25 Kw | ||

| Voltage | 380v | 3 phases | |

Main configuration

|

PLC |

Siemens(Germany) |

|

Frequency converter |

Danfoss (Demark) |

|

Photoelectric sensor |

SICK (Germany) |

|

Servo motor |

INOVANCE/Panasonic |

|

Servo driver |

INOVANCE/Panasonic |

|

Pneumatic components |

FESTO (Germany) |

|

Low-voltage apparatus |

Schneider(FRANCE) |

|

Touch screen |

Siemens (Germany) |

Main Features

- 1) Simple structure, easy in installation and maintains.

- 2) Adopting advanced world famous brand components in pneumatic parts, electric parts and operation parts.

- 3) When there is some change about the production line, just need to modify the software program.

- 4) Running in a high automatization and intellectualization,no pollution

- 5) Robert Palletizer takes less space and more flexiable , accurate compared to the traditional palletizer.

- 6) Reducing a lot of labour and labour cost, more productive.

More video shows

- Robot palletizer for cartons

- High speed robot formation palletizer for cartons

- 24000BPH deep sea water bottle production line in France shrink film packing and robot palletizer

- Modular design robot palletizer saving facotry space

- robot palletizer for two carton packing lines

- Robotic palletizer with two infeed lines

- Robotic palletizer for rice/cement/animal feeds bag