Carbonated drinks filling line

Video Show

Carbonated Soft Drinks Lines

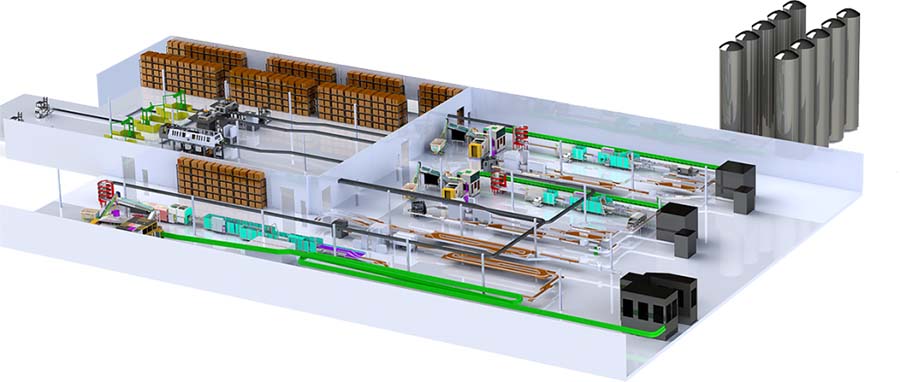

Success in Carbonated Soft Drinks (CSD) beverage production requires focus on flexibility and overall efficiency, with cost-effective resource management and branding opportunities that deliver optimal results across your supply chain. Our unmatched expertise and technical knowledge of PET packaging helps you achieve more.

With over decade years of experience in designing and implementing customised complete PET/can line solutions for carbonated soft drinks, we can help you expand your line’s production capabilities.

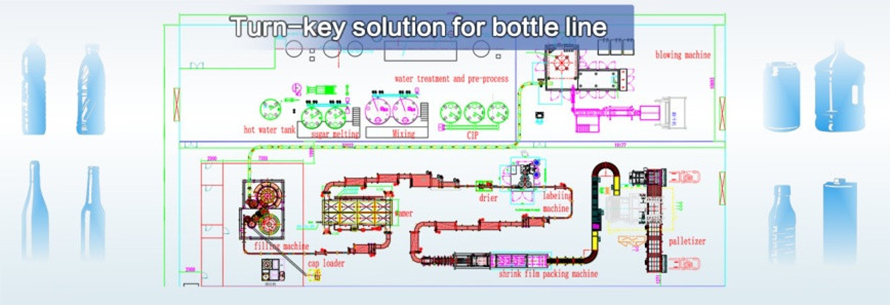

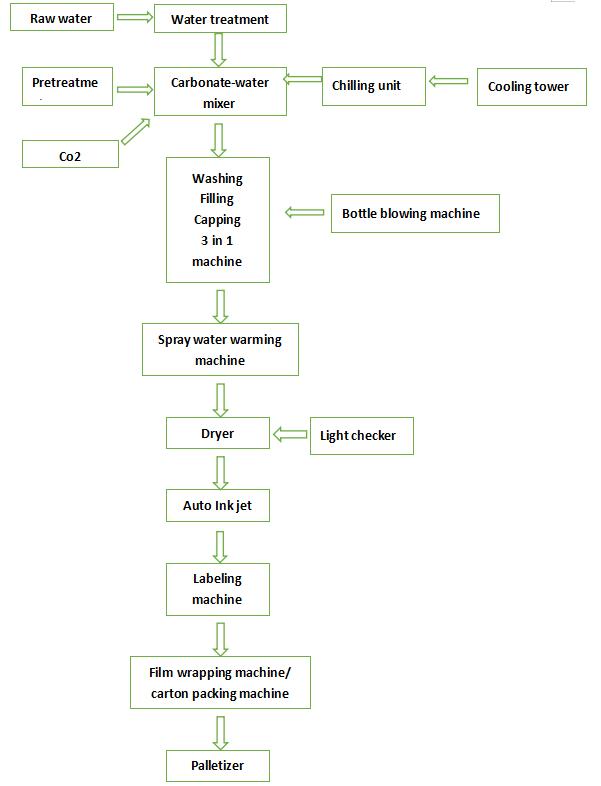

Automatic bottle beverage production line is composed of

1. bottle blow molding machine,

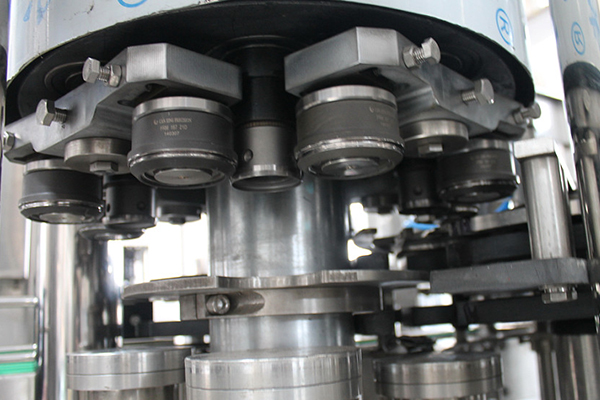

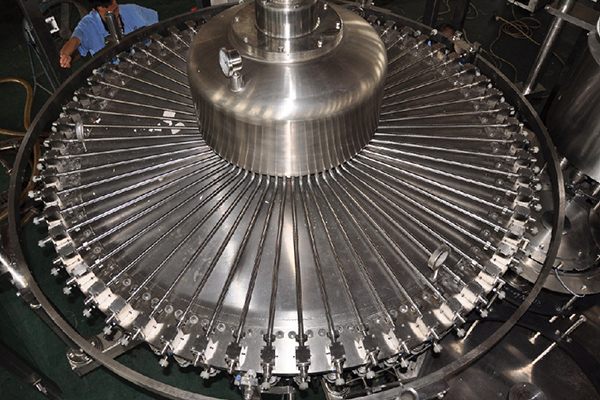

2. air conveyor, 3 in 1 filling machine, (or combiblock machine), CO2 mixer

3. bottle conveyor and light checking

4. bottle warmer

6. bottle dryer and date coding machine

7. labeling machine (sleeve labeling machine, hot melt glue labeling machine, self-adhesive labeling machine, cold glue labeling machine)

8. packing machine (shrink film wrapping packing machine, wraparound case packing machine, pick and place type case packer)

9. carton/ pack conveyor: roller conveyor or chain conveyor

10. palletizer (low level gantry palletizer, high level gantry palletizer, single column palletizer)

11. stretch film wrapping machine.

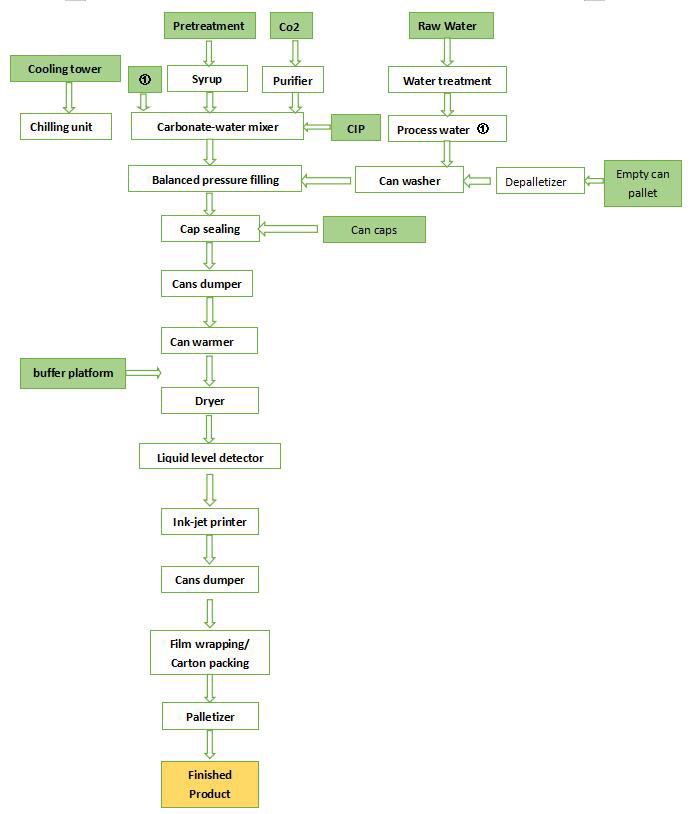

Automatic canned beverage production line is composed of

1. empty can depalletizing machine,

2. empty can conveyor, can washing machine,

3. filling sealing machine, CO2 mixer,

4. can warming tunnel,

5. bottle dryer, Liquid level detector and date coding machine

6. labeling machine (sleeve labeling machine, hot melt glue labeling machine, self-adhesive labeling machine, cold glue labeling machine)

8. packing machine (shrink film wrapping packing machine, wraparound case packing machine, pick and place type case packer)

9. carton/ pack conveyor: roller conveyor or chain conveyor

10. palletizer (low level gantry palletizer, high level gantry palletizer, single column palletizer)

11. stretch film wrapping machine.

One partner for all your needs

A complete CSD line solution from Lilan takes into account every step of your PET carbonated soft drink process, from minimising resource waste to improving your production line efficiency. With everything centred around one supplier, you get wide-ranging expertise, line equipment and ongoing services. This ensures high quality and efficiency from packaging to equipment, fast ramp-up and beyond.